Ex Situ Raman Spectroscopy

#21_Co3O4_Nanoparticle_Electrode

Sample

ELabID: ,Preparation Procedure: The Co3O4 nanoparticle electrodes with a small catalyst loading were fabricated by spin-casting (Laurell WS-400BX-6NPP/LITE) 20 µL of Co3O4 ink at 4000 rpm for 5 min onto a gold-coated quartz crystal microbalance (QCM, BeamTech) resonator, which served as the current collector. The ink was prepared by dispersing Co3O4 nanoparticles (cpy_131_repro_calc) in Milli-Q water to achieve a concentration of 0.1 mg mL⁻¹. The exact catalyst loading cannot be directly derived from the dispersion’s concentration and cast volume. It is, however, approximated to be 1.7 µg cm⁻² at the maximum, as excess solution is expelled from the substrate during spinning.

#43_Co3O4_Nanoparticle_Electrode

Sample

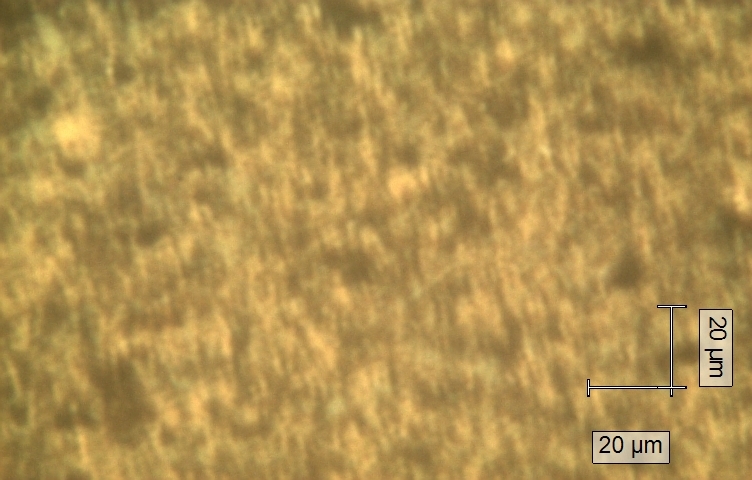

ElabID: CL20250726_001_Co3O4#43, Preparation Procedure:

The Co3O4 nanoparticle electrodes with a high catalyst loading (42.7 µg cm-2) were fabricated by drop-casting 100 µL of Co3O4 ink onto a gold-coated quartz crystal microbalance (QCM) resonator, which served as the substrate. The ink was prepared by dispersing Co3O4 nanoparticles in Milli-Q water to achieve a concentration of 0.5 mg mL⁻¹.

CL20250722_011_Co3O4_#21_50x0p5_L_Image1_small_loading.jpg

CL20250722_011_Co3O4_#21_50x0p5_L_Image1_small_loading.jpg CL20250727_001_Co3O4#43_Image4_0p1M_KOH_high_loading.jpg

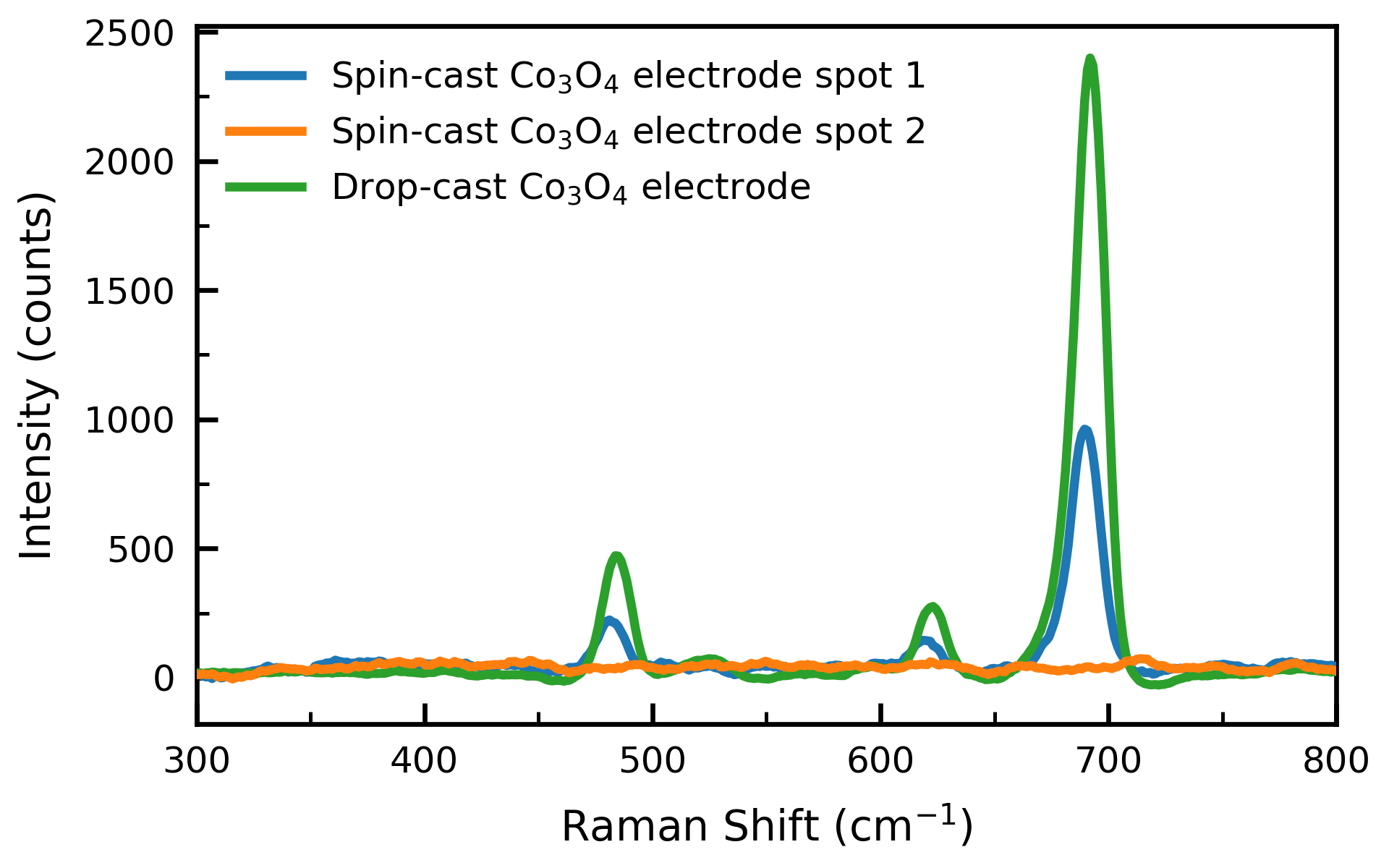

CL20250727_001_Co3O4#43_Image4_0p1M_KOH_high_loading.jpg Spectra_Confocal_Raman.png

Spectra_Confocal_Raman.png